Hello. Advice needed please

Following a test run of the engine there was a loss of compression and oil was seen coming from the area of the head gasket at the rear of the right cylinder. Initially we thought it was a head gasket issue but this is/was a new item.

On stripping the engine (again) I noted there is some damage to the head around about the area where the leak seemed to come from. See pics. Could this be the issue? Would this cause a loss of compression? Seems unlikely but what do I know.

This is a spigoted head. If the fix is to skim the head then what about the spigot on the barrel?

I'm going to try removing the studs and check the head is flat but other than this do you have any advice for how to proceed??

Thanks for reading this far!

Cheers

Are you saying you don't…

- Log in to post comments

The head gasket looks good…

The head gasket looks good and hasn't blown. I will re-anneal before fitting again. The head was torqued as per the manual but I'm wary about overdoing this.

- Log in to post comments

Just to say I actually have…

Just to say I actually have a new copper gasket to anneal and fit. It's not worth the worry of reusing the old at this stage.

- Log in to post comments

You could always try JB weld…

You could always try JB weld as it is only an oil leak.

Put some weld over the bad area, grease/oil the barrel over the same place as the bad area on the head. Replace head on barrel without gaskets, leave for a few hours, should still be soft, lift head off, remove any JB from unwanted areas smooth flat once hardened off.

As for the loss of compression you will need to investigate the valve seats, valve faces piston rings, cylinder bores, and tappet clearances to find the culprit.

At a guess I reckon your tappets are not set correctly.

- Log in to post comments

Thanks - I'll give that a…

Thanks - I'll give that a shot as it's only a small patch. I also realise that I didn't follow the correct sequence when tightening the head bolts. Live and learn.

- Log in to post comments

From past experience

Do not skim the head. Doing so will cause knock-on issues with the barrel spigots, gasket sealing, pushrod lengths and oil leaks.

Your problem could be quite simply that the head has been already skimmed and the spigots are holding the head off the gasket. You can get extra thick solid copper head gaskets but they are not easy to anneal correctly.

Measure up and work out if your gasket is doing its job properly.

Try a composite gasket.

I made a sandwich of a solid copper and composite gasket to prove that my spigots were too long.

Many people will tell you that the Ethanol in today's petrol will affected JB Weld to the point where it makes it goes soft.

- Log in to post comments

very easy to missplace a…

very easy to missplace a pushrod which will give a loss of compression. , usually need to check bolt tightness after first few miles ,then again after a 50 mile gentle run . Also found no valve clearance after someone missread the proceedure to set the engine position.Would not think the damage relevant.

- Log in to post comments

Torque sequences can be made…

Torque sequences can be made irrelevant if you tighten the bolts down gradually a bit at a time until you finally come to the actual required setting, this way any mis sequencing can be of little consequence in the scheme of things.

As for the JB stuff, it does of coarse desolve in ethanol but in this case it wont be a problem to my mind being where it will be situated.

Every thing to gain including the experience of seeing your actions work either way.

- Log in to post comments

You mention the problem was…

You mention the problem was near the rear. Is that awkward bottom centre nut tight? Mine stripped years ago and was helicoiled

JB or similar should be worth a try. The surface we can see looks good. Have you cleaned it after the leak? It's very clean...doesn't look like gas has been going through.

Is there an oil leak from a rocker cover? It can ooze round the joint and come out at the rear.

- Log in to post comments

Morning all. Thanks for…

Morning all. Thanks for these ideas and input. It wasn't the rocker cover.

Since posting my attention was directed to the Oil Leaks section of the Dominator Service Notes and there are loads of ideas there.

First off I'll be checking the depth of the threads and the height of the gasket to see if this is a cause then moving on to follow the advice in the notes and use a bit of silicone if necessary.

Onwards and Upwards!

- Log in to post comments

More Information

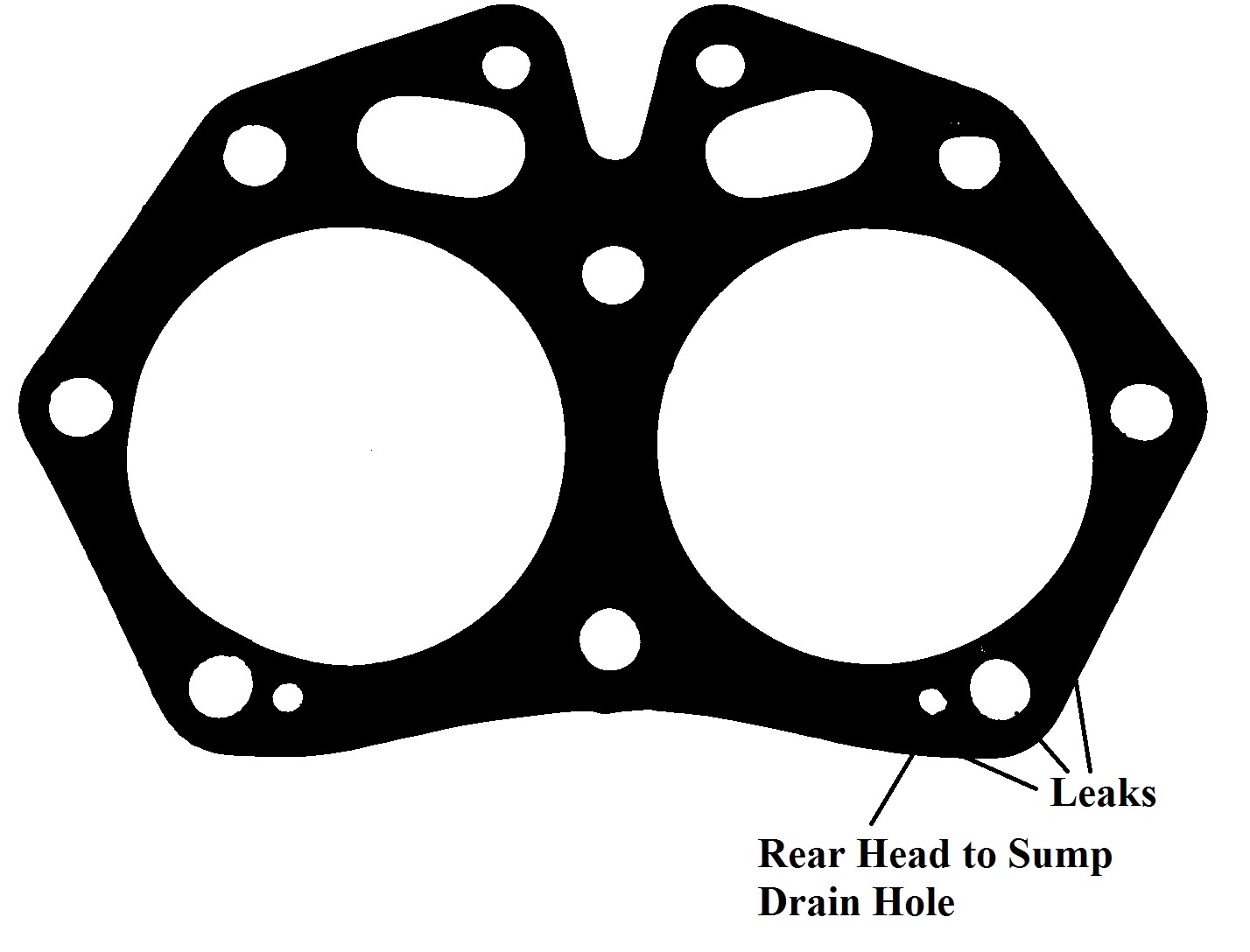

I discovered as follows in the DSNs Oil Leaks section.............

The early 650 and 750 cylinder heads, made at Plumstead, were cast using a very coarse alloy mix which led to porosity issues. These often appearing in the vicinity of the back right-hand side head bolt. This being next to the rear oil drain tunnel which itself gets the full force of any internal crankcase pressure. The leak can be due to oil forced through the gasket in this area or even the metal itself. Back in the 1960s, a temporary fix for the weeping metal was a good clean of the area and then a coating of Araldite warmed with a gas torch to help it get into the pores of the metal.

The photographs show the rear of the cylinder head at the point mentioned above. The drain hole leads from the rear rocker box down to the crankcase. This it does when the pistons are rising. But when falling the pistons increase the pressure within the crankcases. This is used to force oil and oil mist around the engine to lubricate the camshaft, follows, pinions, gears and chains. The camshaft breather takes away a good percentage of the pressure but as well as lubricating the internals oil will get pushed up from the sump, through the drain tunnel and back to the inlet rocker box. On its way, it has to pass through any cylinder head gasket. This is the weak area mentioned above where leaks can occur.

- Log in to post comments

Thanks Phil. I found that…

Thanks Phil. I found that the gasket is not quite correct at the drain hole and was obstructing the flow. On taking the head off there was oil under the gasket. I've filed the hole a bit wider to allow the flow to be unimpeded and will also use Welseal when I come to put her back together again. I hope that's what the issue was.

To be honest the copper gasket is really not a good fit on the barrels. It's definitely the correct item but there are overlaps and I'm sure I'm not the first to moan about the spigot and the extra pfaff involved.

- Log in to post comments

Are you saying you don't have a blown head gasket? It being new certainly doesn't mean it isn't leaking.

Did you re-torque the head after the first time it got hot, then cooled?