On late '40s garden gate singles (ES2 & 30 Inter), what would be a good torque setting to aim for when tightening the engine sprocket nut? And what is the best way to secure the sprocket while tightening the nut? Do any of you utilise a tab washer?

Thanks in advance for any insight.

I made a large peg spanner…

- Log in to post comments

Or Chain Wrench

I use a home made chain wrench to hold the sprocket, and a large ring spanner. Like John no tab washer. No torque wrench either.

- Log in to post comments

I always use a sprag...

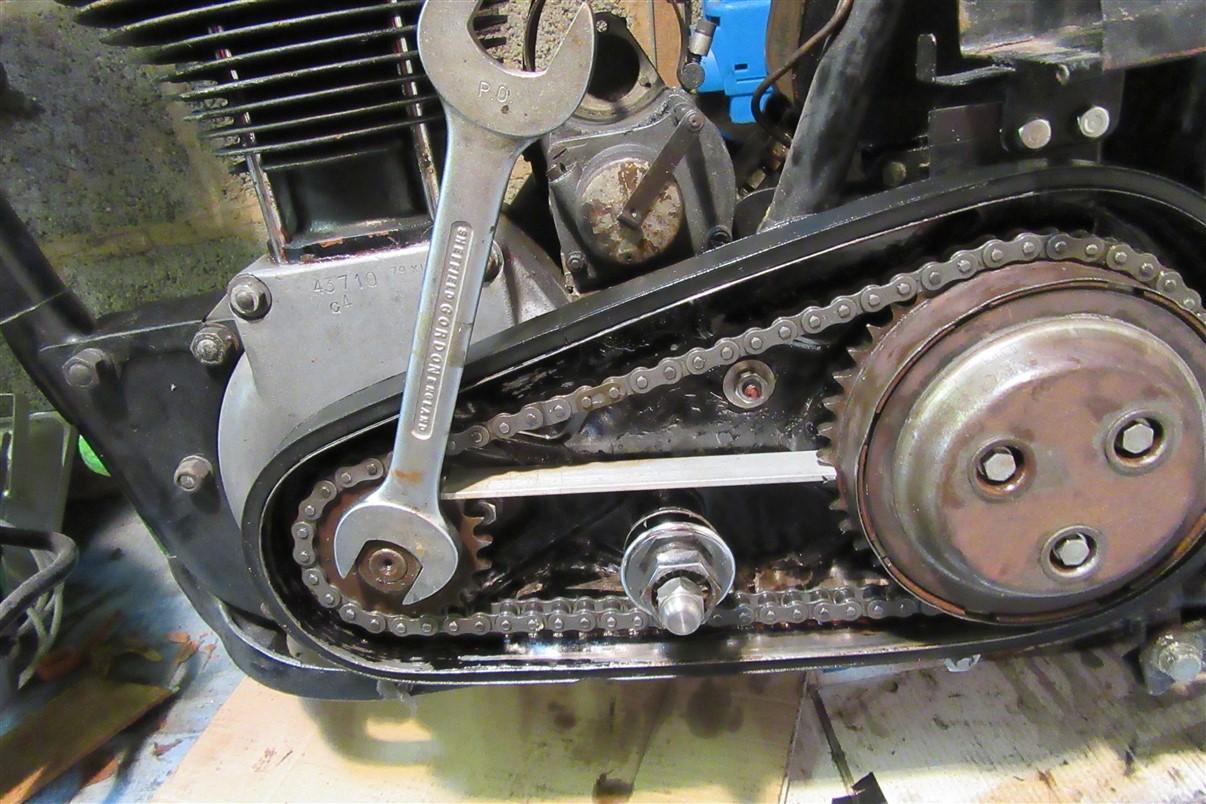

... made of a bit of scrap alloy or mild steel with the edges rounded off. Like this:

Obviously this is for tightening - the same can be used for slackening but with the sprag pointing the other way. A much kinder way to ttreat your Norton rather than wedging things in the spokes.....

- Log in to post comments

Crankshaft nut.

Hi Howard,

to save any adverse strain on any part of the bike I tap the sprocket onto the main-shaft using an suitable size tube and hammer, remembering not to use excessive force. I then use a smear of Loctite on the threads and tighten the nut against compression with-out the chain with a ring spanner and then use a heavy hammer to clout the spanner several times to shock it tight. This may seem a little crude, but is no different to using a pneumatic hammer gun as used (to excess ?) on car wheel nuts. Electric versions of these are available and should be powerful enough for 80 ft/lbs. If the nut was to come loose I don't think a lock tab would be strong enough to stop it.

- Log in to post comments

Thanks very much to all four…

Thanks very much to all four of you for your insightful responses. I like that none of them rely on the primary chain and/or final drive to hold the sprocket as I wanted to avoid putting any undue stress on chains.

- Log in to post comments

Interesting information also…

Interesting information also! Is it a left-hand thread to undo?

- Log in to post comments

Right-hand Thread

The gearbox sprocket nut and the oil pump worm are left-hand.

- Log in to post comments

Splendid, thanks for that. I…

Splendid, thanks for that. I did think as much..

cheers

- Log in to post comments

Can I ask is the band for…

Can I ask is the band for keeping oil out of the clutch plates or holding it in for longer?

- Log in to post comments

I got sick of it coming…

I got sick of it coming loose, so threw it away 50 years ago and never had a problem (I always run oil in the chain case up to the level plug)

l think it's supposed to keep oil out.

John

- Log in to post comments

Clutch plate cover

I think the band came in the thirties, possibly when the oil bath primary came in 1934. Not only on Nortons, other brands had it too. It disappeared in the fifties. Likely because it was useless.

- Log in to post comments

Thanks so much, chaps. I was…

Thanks so much, chaps. I was thinking the same.. I will always ensure that the oil is up to the level, hopefully without leaks.. :))))

- Log in to post comments

I made a large peg spanner to hold the sprocket and use an old fork leg with a square welded to the end to suit a socket, then heave on the fork leg fairly hard. (I've never used a lock tab)

John Doig