My recently rebuilt 56 Dominator 99 has an oil leak and I don't know where it is coming from.

Starting the bike from cold, and running for about 5 minutes, oil appears on the timing case in the area of the oil junction block bolted to the engine. It is above the junction block and below it.

If left like this overnight, there is a small puddle of oil below the bike.

The bike is cold so there is no oil vapour in the timing case.

As far as I know, there is no pumped supply up to the area of the magneto in the timing case. If the magneto was not bolted up properly (that bottom nut is a sod), there would still be no oil up there and no pressure to force it out.

There is no leak from the timing case/outer cover joint.

I suspect that the oil junction block may be cracked, but looking at it closely, no crack is apparent.

Does anybody have any bright ideas?

Thank you.

Magneto nut

- Log in to post comments

Drips

Several potential leak points and causes on this model.

a) On a cold start-up, the pressure release valve inside the timing cover will get pushed back and allow oil to flood that part of the bike. It will continue to do this if the PRV spring is tired or until the oil has warmed up. Using 20W/50 oil may help.

b) You might have a leak in the oil pipes to the feed block.....or the gasket behind the block is leaking. perhaps one of the block arms or its solder has cracked.

c) Leaking Magneto gasket or bolts/studs.

d) Dodgy timing cover gasket or warped cover.

- Log in to post comments

Talcum Powder

Richard,

one dodge is to totally degrease the area with degreaser, when it's dry spray talcum powder over the area, and start the engine.

The leak will be very obvious.

- Log in to post comments

Thank you all.

...for you helpful suggestions.

I think I'll take Phillip's points one at a time.

Looking at a), I'll get the bike well warmed up, then start it again after a few minutes. If the PRV spring is weak, hot oil will appear - but how does it get out of the engine?

b) I have looked closely at the pipes from the tank to the engine, there is no oil on them nor around the hose connections. A cracked junction block may be the problem, but I think there is too much oil appearing too quickly for it coming from a fine crack.

c) Leaking magneto gasket is certainly possible but surely the timing case doesn't fill with oil such that it is pumped out past the gasket.

d) Leak from the cover gasket - very unlikely, I have carefully checked all around the joint, there are no leaks there. But again, how would the oil level get so high in the timing case that it runs out of any leak?

- Log in to post comments

is the engine breather clear…

is the engine breather clear. its already been mentioned. but ive had a leak from a crack in the solder on a pipe that fits into the junction block. at first i couldnt spot where the leak was coming from. so took the pipes off and you could swivel one of the pipes from side to side. so i had them re soldered.

barry

- Log in to post comments

Thank you Barry

The junction block and the two pipes appear very second hand and abused; Looking closely with a magnifying glass did not show any likely crack but I'll look further - maybe replace the two pipes as well.

- Log in to post comments

More

I've checked the junction block (filled each leg with petrol and blew hard), no leak.

The leak is definitely coming from the magneto/crankcase joint.

Before I strip it all, I must check that the bottom nut is tight.

It seems to be 1/4" W.

Does anyone have an idea about how to tighten it?

Even if I take the mag off to check the gasket (how do I get it off?) I must tighten it again to put it back.

Richard

- Log in to post comments

Bottom bolt

I only use the extended bolt shown in Michael's earlier post. Makes it simple to ensure that the magneto flange is uniformly tightened.

There are spanners available which give better access but the extended stud is by far the best way to go. Available from all of the major parts suppliers

- Log in to post comments

Long bolt may not work.

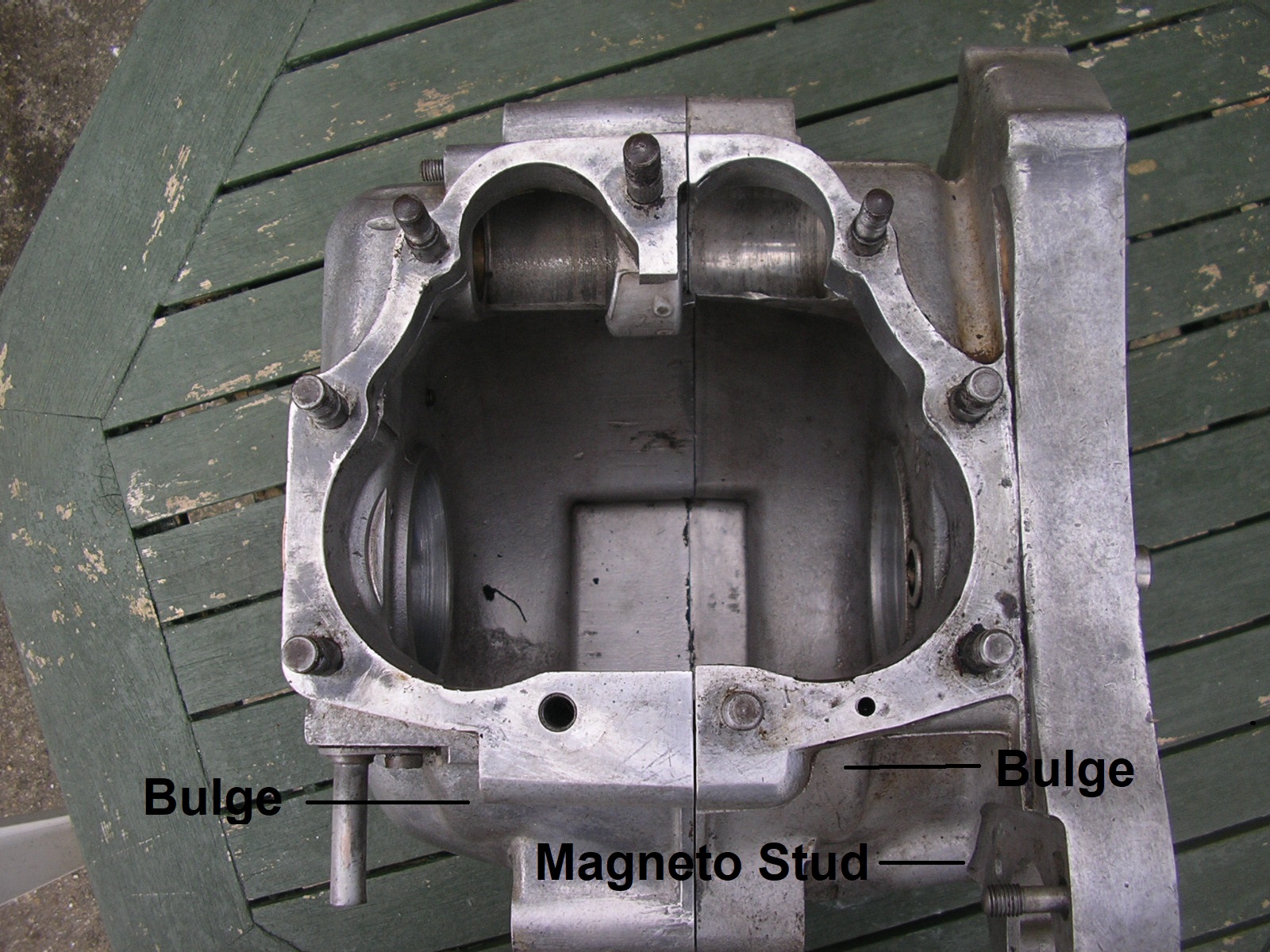

Did the '59 99's get the bulged cases? If so, then the long bolt wont work as it hits the crankcase centre flange.

The 650's and up had the inaccessible bottom bolt reversed, ie. the nut was inside the timing case. Does make it a lot easier to tighten the mag/dizzy/ei housing, but a pita as it is yet another oil leak path to be resealed.

Can the bolt be reversed on earlier engines? That I don't know.

Regards George

- Log in to post comments

Magneto Fixings

Earlier crankcases generally had 3 external studs

- Log in to post comments

leaks in the mag area can…

leaks in the mag area can stem from too much engine "breathing" from bad or not run in rings, Also a 6 start pump sending too much oil through the PRV , A stuck piston in the PRV , A collapsed or bent breather pipe . thick cold oil causing higher than neccessary oil pressue ,try a 20/50 . The Bulge cases may have been fitted to a few of the later 88/99 engines ,but not a 59 .

- Log in to post comments

Bulged Crankcases

As can bee seen in the photo below the crankcase bulges are well clear of any extended bolt used to fit the magneto. The problem with all of the Dominator engine is the flange lips which could be trimmed a little to clear the bolt shaft.

The extended bolts themselves do tend to vary in dimensions depending on the source of manufacture. Michael C in his posting above agrees with my findings. eg the BSA bolts have a thinnish, unform shaft that generally clears the Norton Crankcase flanges. A trial fitting is a smart move and if required, some metal removing is easily done with a drill and file.

- Log in to post comments

More checking

The oil leaks from the mag flange as soon as the engine has started. It stops when the engine is off.

So it's being forced by some pressure somewhere. I don't understand how oil can be so high up in the timing case to be forced out by pressure. Vapour when the engine is hot, I can understand.

Besides the gasket, is there any other seal which might cause this by leaking?

I'll be taking the mag off to check the gasket. I carved up a spanner to (partly0 fit the nut, I hope it works today. I had to take a lot off.

The extended nut won't fit on my engine, the crankcase is in the way.

I like the idea of a stud coming in to the timing case.

Robert, thank you for the tips. The engine has done only 100 km since rebuild. It doesn't have a 6 start pump. I'll check the piston in the PRV.

- Log in to post comments

Thank you ...

.... for you information and tips this morning.

- Log in to post comments

External bolt and nut inside…

External bolt and nut inside timing cover: I did this many years ago on a Dommie engine I was working on. Difficult to remember for certain, but you might need to remove some of the "meat" where the base of the stud sits inside the case, to ensure enough clearance when you have the nut in place so it clears the back of the magneto gear.

- Log in to post comments

hello, is the oil seal on…

hello,

is the oil seal on the magneto and the crank ok. worth checking.

barry

- Log in to post comments

Thin Nuts

Michael has raised another good point. The reversed bolt into the crankcase is one solution to the magneto flange issue but can cause other issues such as clearance for the magneto chain.

With the bolt facing outwards, it can have a thin, domed head due to the need of only 12flb torquing of its external nut.

Reverse this set-up and you then have to consider bolt thread length, nut thickness and secure fitment.

With regard to oil in the timing cover......a cold engine start-up will almost certainly trigger the pressure release valve into dumping oil inside the cover.

This is added to by oil in the sump which the descending pistons will actually push up through the two oil drain tunnels into the timing cover. This is part of the engine design and is known as the 'bellows effect'. The idea behind the design is to lubricate the chains, timing gears and oil pump from the first turn of the motor.

Pressure inside the crankcase is high and unfortunately, the tiniest of gaps in gaskets or mating surfaces will allow oil vapour to pass through and form stains, drips and puddles.

- Log in to post comments

I have a dedicated flat…

I have a dedicated flat combination spanner. The edges of the open end have been ground back from about 3/16" maximum to a point at each tip. The edges of the ring also ground away. And the offset angle of the ring from the handle is hammered flat so it can be reversed. Remove the oil union and it works. Hard part is getting the nut started.

- Log in to post comments

Finally,

Finally, I have found the cause of my problem.

The oil was leaking from the magneto/crankcase joint.

Using a ring and a flat, extensively ground, I found all three nuts reasonably tight, and that there was a thin paper gasket in place.

However, on the upper edge of the mating flange, there is a riveted aluminium label stating "Lucas Racing Magneto".

This label was protruding beyond the face of the flange by a small fraction of a millimeter, enough so that the face could not be pulled up tight to the crankcase.

No problem with a thick gasket but allowing oil to escape with a paper one.

A few minutes with a file removed this overlap.

The engine is running again and so far, there is no oil leak.

- Log in to post comments

A great magneto to have on a…

A great magneto to have on a Dommie - K2FR quite rare and expensive these days. The later Atlas and 650 SS (and Mercury) had a waisted bolt with a reduced hex bolt head, reduced diameter 5/16th flat washer, a small 5/16th fibre washer and inside the timing cover, another 5/16th fibre washer, followed by a flat washer and lastly the 5/16th cycle nut. This makes an oil- tight sandwich around the mag/ or twin-points holder , gasket and crankcase. It is probably hardened so that it does not snap off at the 1/4 inch step. Even with the waisted studs on the earlier bikes, the three 5/16th cycle nuts and washers should be reduced hex for easy access ! Good luck, Howard

- Log in to post comments

Not really much help in the present circumstances, and yes that bottom nut is a pain BUT there is a solution. There is an extended bolt available, I think originally for the A10 but will fit most brit bikes of the era. About 3"/15cm and less than a fiver. But you would of course have to faff about removing the original nut in the first place.

https://www.feked.com/bsa-a7-a10-magneto-bolt-67-1259.html