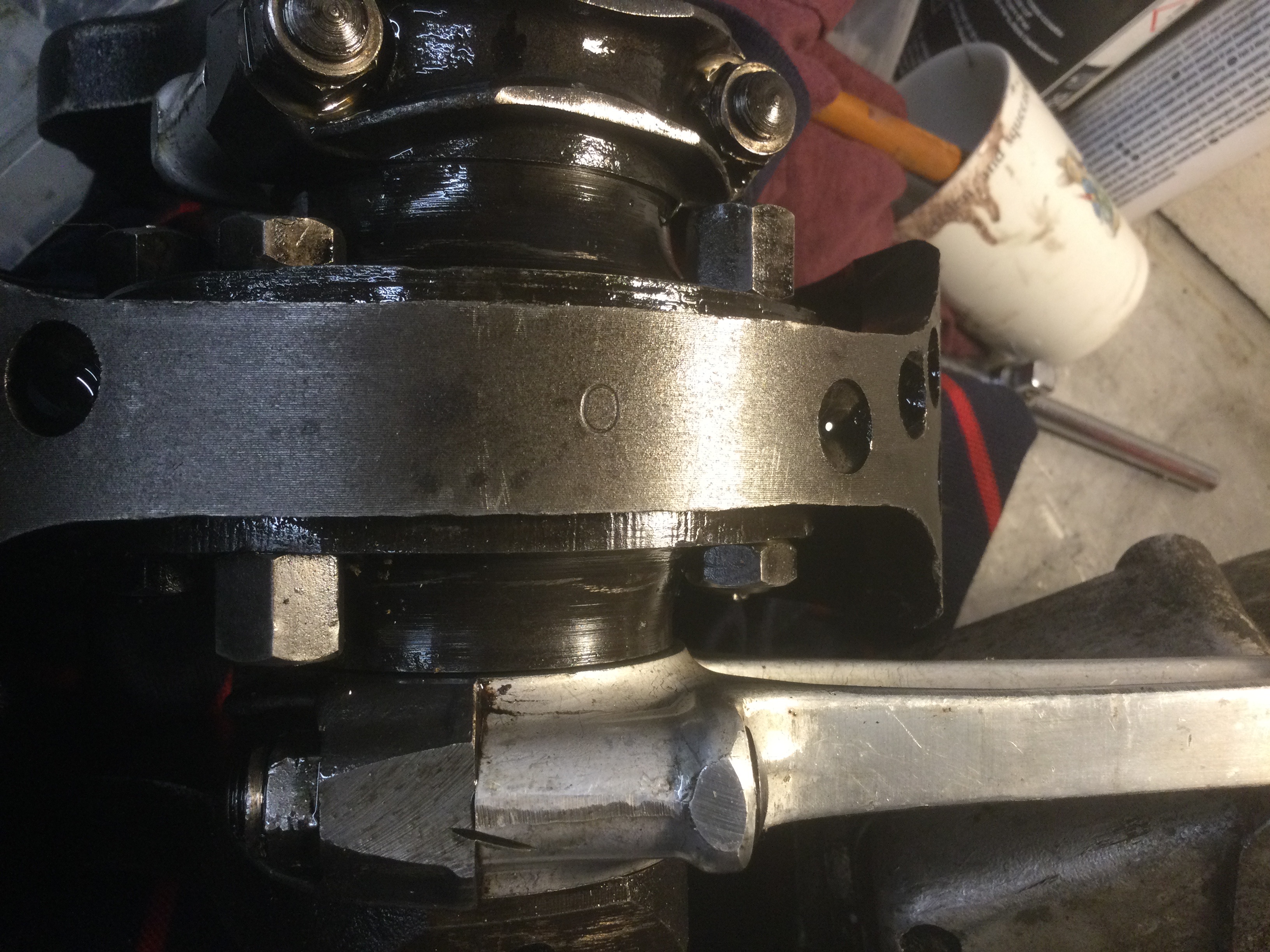

I am striping a 750 Atlas engine (actually from N15CS) and everything is in excellent condition which make me think it has been rebuilt. However looking at the crank flywheel nuts and bolts something looks odd.

there is a mixture of thin nuts, deep nuts and standard length nuts, some deep nuts are on different side and no fixed pattern. Also some nuts have been centre punched to lock onto bolt.

deep nuts and standard length nuts, some deep nuts are on different side and no fixed pattern. Also some nuts have been centre punched to lock onto bolt.

All this makes me think

1 is this standard (surely not)

2 is it a sign it has been dynamically balanced

3 is it just shoddy work

Thanks Richard

Looks odd to me. You don't…

- Log in to post comments

Thanks for replies Looked…

Thanks for replies

Looked further and found evidence of having "heavy" metal welded in.

My guess has been balanced and maybe used the different nuts for fine tuning

Richard

- Log in to post comments

It's a long time since I…

It's a long time since I took mine apart. But I do remember it being very difficult to get a good purchase on some of the nuts, being behind the flywheel flange. I thought some nuts were deeper than standard simply to make themselves more accessible, and some were shallow to miss the conrods. They might or might not be in the designated positions. Perhaps it will become clearer when you try to loosen them? I don't know what PO did with mine, but they were very difficult to remove.

(and when rebuilding; the Haynes manual 'famously' has the wrong torque value. It says 35 instead of 25 lb.ft)

Also: the manual instructs you to 'stake' the nuts, so that is as per book. I don't know why you shouldn't use the same tab washer plates as the one that retains the dowel. Does anyone?

- Log in to post comments

Andover Norton cranshaft fitting kit ( Nuts and Bolts )

I`m just rebuilding my Dommi 88 crank and bought a kit from the above. It has 4 `Bolts` and 2 `Studs`. Two of the nuts on the studs are Long and are only threaded part ways through. Anyone know which way around these long nuts are to be fitted ? They don`t fit nicely into the bored surface either. The Tab washers also seem not to fit flat . I have tried phoning them today but couldn`t get a reply. E mailed them tonight too but found this thread and thought I`d tag on . Hope that`s ok ?

- Log in to post comments

Yes, that does help a bit…

Yes, that does help a bit although Ashley at Andover Norton has told me all the nuts should be the same and is sending me two short one`s to match the rest. Thanks.

- Log in to post comments

The longer nuts are to…

The longer nuts are to permit spanner access and because they are beyond the threaded part of the nut the centre pop is used to lock the nut by carefully going down inside the nut to pop the point on the bolt where the nut and the thread meet. I usually do both sides On the shorter nuts the spanner access is not a problem and the centre pop can access the thread junction with the nut directly. Short nuts in the position where the long ones should be will be a problem for you. Good luck, Howard

- Log in to post comments

Looks odd to me. You don't balance a crank by using assorted nuts. As you already have the crank out, I personally would split it- check/clean out the sludge strap- and get a full matching set of crank fittings from a reputable supplier.

Peace of mind- can't put a price on that!