The bike is 12V positive earth from when I got it and I have already upgraded to a an Al Osborn A Reg 1 solid state regulator, stripped the carbs, ultrasonic cleaned them and fitted new jets throughout and fitted a longer kick start lever.

To overcome poor starting due to what I believe to be a weak spark (improved with longer lever), I am changing from points to an electronic ignition system.

I am using the Thorspark system which retains the magneto but replaces the points with an electronic pickup unit in the original points location and introduces a coil.

The system will require an ignition switch.

Long story short, I would like to replace the current 41SA light switch located on the headlamp shell with a PRS8 switch which includes an ignition switch with the light switch, fits in the existing mounting hole in the headlamp shell and should retain the original period appearance.

Can anyone assist with the wiring arrangement for this – I am working with the diagram attached as a base point (although it is 6V, it is positive earth).

Does the black wire from the new solid-state regulator go to ignition switch terminal 13? (brown on diagram)

Do I add/splice a wire to the GB and WG from the alternator which connect to the yellow wires on the regulator and then connect to terminals 7 & 4 respectively on the light switch?

Do the red and black wires from the new coil connect to terminals 15 & 14 respectively on the ignition switch? (according to polarity indicated on diagram)

Finally, can I retain the single wire that went from the kill switch to the end of the magneto to continue to act as a kill switch independent of the ignition switch?

If so, where is the best place to connect this to the ignition circuit?

Thanks for any assistance.

Alastair

12V with PRS8

- Log in to post comments

You could use...

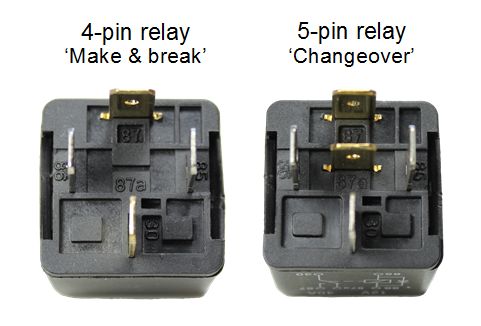

... a changeover relay. Connect terminal 86 to a switched ignition live and 85 to your handlebar stop button (assuming this is earthed when pushed). Break the live feed to the thorspark and connect the live side to terminal 30 and the thorspark side to terminal 87a.

So under normal running circumstances the feed to the thorspark will be uninterrupted. Pressing the kill button will energise the coil in the relay and open the circuit to the thorspark. It would be failsafe in the sense that its "normal" condition would be "run". And it won't draw any current unless the button is pressed.

- Log in to post comments

Seems excessive...

Seems excessive, you arrive at your destination, press the switch engine stops. You let go the button, the ignition is 'on' so the machine is 'nick-able', and your battery is running down. You then have to have an ignition warning light of some sort.

This would seem another doubt in the belief of 'Electronic ignition to replace a failed magneto'.

- Log in to post comments

On / Off

All of my Electronic Ignition Kits that used a coil needed an on/off switch in the form of an Ignition Key.

This basic key operated switch was purchased from eBay for just a fiver. It was fitted to an 'L' bracket attached to the top battery box bracket and quite simply turns on or off the power from the battery to the ignition module.

- Log in to post comments

Al...

... I wasn't suggesting the relay as an alternative to a switch, which of course would also be needed for a thorspark or similar. I was just answering Alastair's query re a kill switch - he does mention an ignition switch in his question. I must say I've never actually found the need for a kill switch and in fact have generally found them more trouble than not.

- Log in to post comments

Wiring Diagram - Without Kill Switch

Kill switch not a big deal - just wondered if it was possible as on Japanese bikes I have had in the past. Happy to proceed without one.

The attached diagram is where I have got to with regard to incorporating the PRS8 switch with Thorspark electronic ignition.

Is there any fault with this?

I don't want any smoke to escape from the wires.

- Log in to post comments

There are..

There are several mistakes in this diagram which I have dealt with direct with Alistair. Do not use this diagram.

- Log in to post comments

Diagram Removed from Previous Post

PRS8 switch now fitted and lighting side seems to be functioning correctly.

Ignition also switching correctly with green wire to ignition unit wired to terminal 13, although just using a test bulb for the moment.

Final wiring connections between coil and Thorspark unit in magneto to complete before test starting and final timing adjustment with strobe light.

Just some clarification required on the current non-standard alternator wiring arrangement - there are only two wires, where it seems there should be three.

A green/ yellow wire from the alternator goes into a double bullet connector and emerges as two green/ black wires which are then connected to one of the yellow wires on the A Reg rectifier.

A white/ green wire from the alternator goes via a single bullet connector to the other yellow wire on the A Reg rectifier.

This is basically how the connections were made to the original rectifier and zener diode which have now been replaced.

However, the original battery was dead and dry - that is what originally sent me down this rabbit hole!

- Log in to post comments

Re Thorspark. I have a key…

Re Thorspark.

I have a key switch in the supply line that feeds it on my Matchless, gives a bit of security along with the QE11 anchor chain round the front forks.

- Log in to post comments

Success

All sorted now - starts first kick and runs great.

However, it has now developed a pretty major oil leak from the primary drive area.

When I was in there to set up the ignition timing it turns out that it has had a belt drive conversion fitted and the case area was pretty dry - well only slightly moist.

Any suggestion of where to start looking for how the oil is now getting into the primary drive area?

I think it is engine rather than gearbox oil - is there a crankshaft oil seal behind the alternator, and if so, can that be replaced in-situ reasonably easily once the alternator is out of the way?

- Log in to post comments

Yes, Alistair, there is a…

Yes, Alistair, there is a gaiter crankshaft seal next to the main bearing that can be replaced after removing the alternator. The seals can simply wear out, or the gaiter can be blown outwards by excessive crankcase air pressure or wet-sumping. Be worth making sure the crankcase breathing is okay and that there is not too much oil building up in the crankcase when the bike is left for a while without starting.

- Log in to post comments

Seal can be pulled out with…

Seal can be pulled out with a couple of self tappers ,but you have to remove the alternator and engine sprocket which will need a strong puller. The orriginal solid 2 leg one is best . Rgm have sold them ,part 067500 £ 22

- Log in to post comments

Thank you gents. Will order…

Thank you gents.

Will order a couple of seals and a solid 2 leg puller.

- Log in to post comments

A

I very much DOUBT you can retain the h/bar ignition kill from the mag. You have to look in detail at the Thorspark ignition diagram, I have not got it, nor have I even been privileged to see it. Thorspark are the people to ask if it is not on the diagram.

The new ignition coil is to be connected to the Thorspark unit. You need a supply to the Thorspark from the PRS8 14 with a supply from the ammeter to 13. The Negative output from the A REg1 goes to the ammeter, this connection also feeds the light switch 2 and 10 and 13. There is NO connections from the alternator EXCEPT to the A reg. (any alternator wires were for emergency start with 6V coil which you do NOT have)

I think that covers your points below. Al O