Took my 1973 750 Commando for the first run in my ownership today. Noticed oil dripping from engine fins when engine running but I can’t see the source. It’s dripping from the right hand exhaust port nut fins and from a head fin, but I think that’s running from the port area. Can anyone advise what might be the source?

Rocker cover if you're lucky…

- Log in to post comments

Not the rocker covers …

Not the rocker covers (already cured that leak!).

is there room to get the head off without removing the engine?

- Log in to post comments

Check the inlet rocker cover…

Check the inlet rocker cover too as it can run through and appear at the front.

Yes, the head can come off in situ. It's a fiddle but possible.

- Log in to post comments

I didn’t check that one so…

I didn’t check that one so will do. It’s leaking quite fast :-(

- Log in to post comments

Just figured out to add…

Just figured out to add photos :-)

wonder if I can add a video I’ve got….

- Log in to post comments

Cylinder head castings

The Commando head casting is a complex thing. The favourite leak appear three fins up..I can't quite see from your photos. It could be either the inlet rocker cover, or perhaps more likely, any of the rocker spindle cover plates. It's where the internal galleries in the casting all meet up.

If the oil is clean, as yours is, you'll hardly be able to see it migrating under the cover plates and down into the centre where it picks up a bit of road dirt and emerges as a visible leak.

- Log in to post comments

Check the nuts on the studs…

Check the nuts on the studs either side of the centre bolt, peer in with a small torch. If there is oil on the nut it is coming up the stud. Easily fixed without removing the head.

- Log in to post comments

The threaded hole...

... for the studs Ashley mentions can break through into the pushrod tunnels. Happened on my 850. A bit of loctite sorted it out bt needed the head removing.

You have plenty of possibilities here Graham.

- Log in to post comments

Thanks all, detective work…

Thanks all, detective work then :-)

- Log in to post comments

Note that although removing…

Note that although removing the head in situ is relatively easy, replacing it is definitely not …

- Log in to post comments

Oil Drips

1) The 750 range of Norton engines had breathers which could not cope with the volume of gas being asked to squeeze through holes that were too small in cross-section. The Atlas and early Commando motors trying to push excess oil vapour up through a piece of rubber tube into a tank. This was often next to impossible and quite often instead, the vapour headed out through a worn crankshaft oil seal and over-loaded the primary cases. Generally making the owner think that oil was being drawn through the gearbox mainshaft. So check the crankcase breather elbow and the tubing for any gunge blocking the exit route.

2) The internal crankcase pressure in the 750 engines is not restricted to the bottom half of the motor. High pressure gases would flow up past the camshaft followers into the head and happily leak out of badly sealed rocker covers, rocker end plates and the 1/4" BSW / UNF bolts holding the end plates in place. This last point is quite often the one missed by people rebuilding 750 Norton engines. These bolts usually have only a couple of sloppy threads to do their job of holding the end plates in position and generally are quite a slack fit. There are two moves which can help with this issue. First apply some High Temperature sealing goo to each bolt thread. Secondly, add a small copper washer under the head of each bolt. Some Decoke kits have these as part of the package.

3) Check out the attachment. This shows what happens if a composite head gasket is used on a 750 engine. These have two weak points where crankcase pressure will push oil through the composite sandwich to the outer edge of the barrel/head joint. The first being the push rod tunnels. Any splits in the gasket rings that seal the push rod tunnels will let oil straight past.

The same can happen at the rear of the barrel where the oil return/drain hole passes through the gasket. For some reason, unless a solid copper gasket is used, there is no protection at all stopping oil from being pushed sideways inside the gasket in this area. It then heads for the nearest exit which happens to be the cylinder head bolt behind the spark plug. From here it is pulled forward by the reverse airflow which happens on a Commando engine appearing on the third fin at the front of the engine.

- Log in to post comments

I always used...

... a well annealed solid copper head gasket on my 850 with a minimal smear of Wellseal around the pushrod tunnels and never had oil leaks from there.

- Log in to post comments

To add a little more... As…

To add a little more...

As Ashley says, could be coming up the front studs - try re-torquing the head.

As Philip says, could be related to crankcase pressure and the tacho drive is another source of oil blowing over front right hand side of the engine.

An old trick for tracing hard to find leaks it to thoroughly degrease the engine, dry it (maybe with a hot air gun or similar) and dust with chalk or talcum powder (whatever's to hand). Then run the engine, the leak will leave a tell-tale trace in the powder.

- Log in to post comments

Thanks all for the ideas. I…

Thanks all for the ideas. I hope to have another look at the engine next weekend

- Log in to post comments

More on Oil Drips

The pushrod tunnels are clear suspects when it comes to remaining oil tight. If you look at the physics of those areas when cruising your Norton along at 70MPH then a couple of points need to be considered.

First the temperature of the metal on the inward side of the pushrod tunnels is going to be near that of the combustion chamber. So probably in the region of 300*C or more. Whereas on the outer tunnel face, the oncoming airflow will have brought the temperature of the metal on that side right down to most likely just double figures.

This means that the metal of the inner tunnel side will be trying to expand like mad while that of the front fin side will be nice and comfy and resting easy. This differential expansion can not be good for keeping the gasket oil tight around the pushrod tunnel. Hence the addition of a small amount of gasket goo around the eyelets is a smart move just in case some distortion occurs.

- Log in to post comments

Engine breathers

May be worth a try...

On my 69 750. Seemed to be oil leaks from the head gasket area. Bought the gaskets and sockets so all ready for it.

Checked the forums then decided to drill the rear rocker cover (lower part) and add a breather tube from the rocker cover to the oil tank breather. Added a tee piece to the tube from from the crank elbow to the oil tank and then added a small pcv valve in line from the crank breather so the rocker gases didn't blow back to the engine case. PCV behind the side panel to keep it hidden. Pretty easy and cheap.

Head oil leaks either went away or now hardly noticeable. Two (obvious leaks) now remaining- the tacho housing and the right hand rocker oil feed banjo.

Eddie

- Log in to post comments

Over - torquing

The first post-WW2 Norton 750 bike was the Atlas. This had a very thin and weak head gasket that allowed oil to leak past it as soon as the engine was revved. One of the causes being the head bolts each side of the spark plug were only 5/16" with torque settings of just 20ft lbs. The same as the two front barrel studs.

Owners would conclude that a few extra lbs of torque on all of the head bolts would cure the gasket leaks and set to work with a socket or spanner set. Remember in those days few people owned a torque wrench and generally any that were available were for car bolts set at 50 ft lbs or more.

Consequently, heavy hands made light work of the 5/16" bolts and nuts and extractors became the favourite tool of the year.

On the 650 Manxman (1961 to 62) the rear rocker cover had a specially hollow fixing bolt breather that ran to a collector container. I fitted one of these to my Manxman engine and discovered that with a pressurised rocker feed this bottle filled up within 20 miles of road running. It worked ok with a low pressure feed but on a post 1966 engine there might be problems. What did work for me was converting the exhaust covers to accept twin breather made out of old carb main jets.

These breathed into a chunk of foam and that cylinder head never leaked from anywhere.

- Log in to post comments

Lots of positive reports…

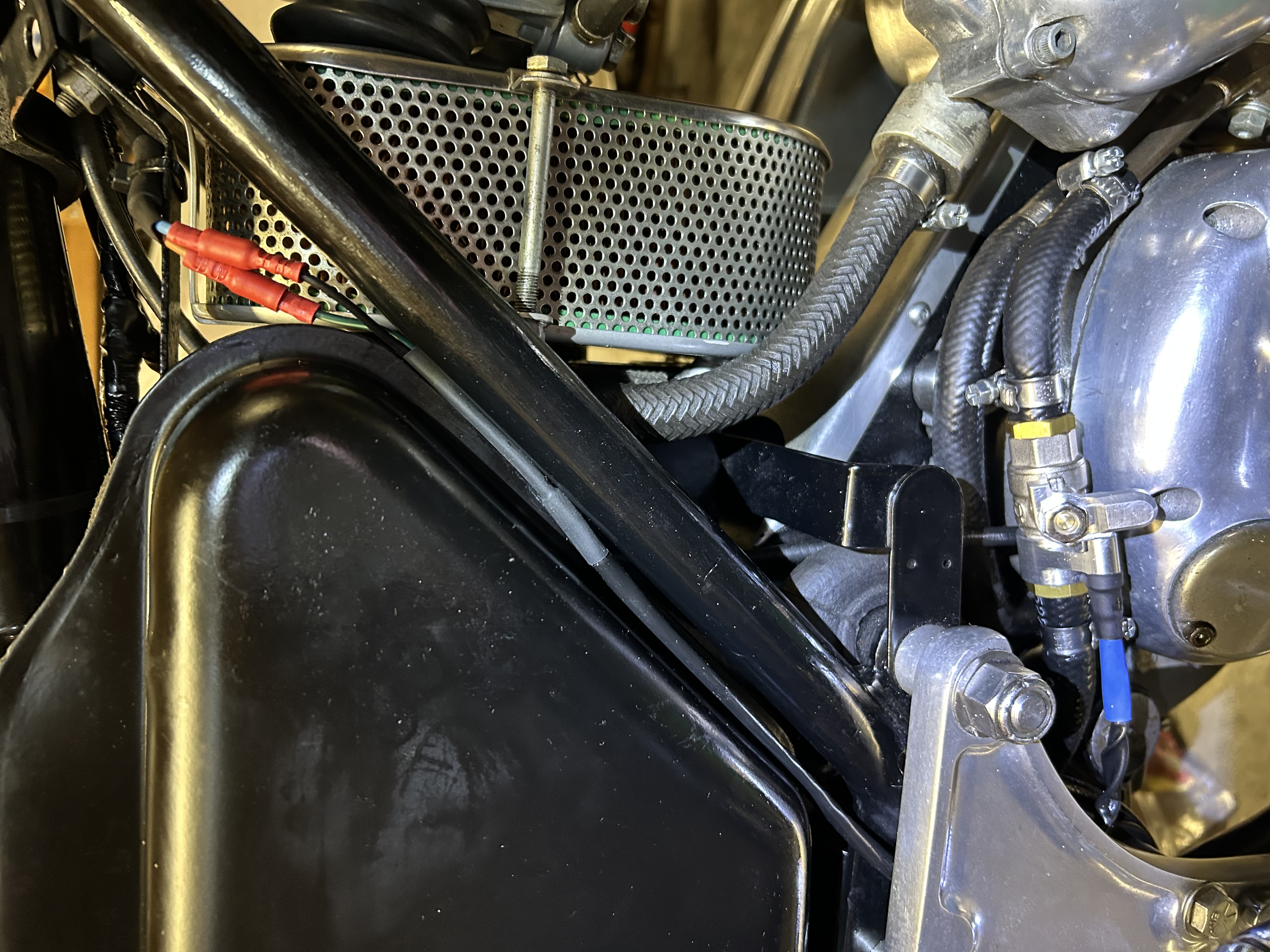

Lots of positive reports about fitting a pcv. My 750 engine dates from 1972. It’s got the breather shown in photo. Is there a Pvc which is same connection size as the standard hose so that I can fit it without adaptors?

Regarding adding additional breather connections, are those applicable to my engine (I gather the arrangement changed for commandos)?

- Log in to post comments

Found it (I think)!

Copious dusting of talcum powder and idled the bike for 10 minutes with occasional high revs.

Noticed leak into the points/timing chamber, out of the drain hole and onto the exhaust pipe.

I guess this means a shaft seal is leaking and needs the casing removed?

Also I noticed a drip on the kickstart spline so I guess that shaft seal needs replacing too.

- Log in to post comments

Timing cover needs to be…

Timing cover needs to be removed to replace camshaft oil seal. There is a tool to aid refitting - has a taper to lead the oil seal over the end of the camshaft. You can do it without with care, maybe put some PVC tape around the very end of the camshaft.

But that's a long climb for enough oil to drip off the exhaust nut.

Everyone's kickstart looks like that :). There are various tricks and mods to reduce the kickstart shaft leak - a search here will throw them up.

- Log in to post comments

It is a long climb so I’m…

It is a long climb so I’m still suspicious. I’ll take it for a blast tomorrow and check again. Not sure the talcum powder will stay in place though.

- Log in to post comments

Rocker cover if you're lucky, head gasket if you're not.